PPO is a thermoplastic engineering plastic with excellent comprehensive properties. The temperature resistance of PPO plastic is between 280 degrees and 330 degrees.

1. The dielectric performance is the first among engineering plastics: there is no strong polar group in the molecular structure of PPO resin, the electrical performance is stable, and it can maintain good electrical performance in a wide range of temperature and frequency. Its dielectric constant and dielectric loss tangent are the smallest among engineering plastics, and it is hardly affected by temperature, humidity and frequency. Its volume resistivity is the highest among engineering plastics. The excellent electrical properties of PPO make it widely used in the production of electrical products, especially high-voltage components, such as line output transformers (FBT) of color TVs.

2. Good mechanical and thermal properties: The molecular chain of PPO contains a large number of aromatic ring structures, and the molecular chain is highly sensitive. The resin has high mechanical strength, excellent creep resistance, and has little effect on temperature changes. PPO has high heat resistance, the glass transition temperature is as high as 211°C, and the melting point is 268°C.

3. Excellent water resistance: PPO is an amorphous resin. In the normal temperature range, there is less molecular movement, there is no large polar group in the main chain, no dipole moment occurs, and the water resistance is very good. It is the plastic with the lowest water absorption rate in engineering. After soaking in hot water for a long time, its physical properties are still rarely reduced.

|

Physical Properties |

Metric |

English |

|

Specific Gravity |

1.06 g/cc |

1.06 g/cc |

|

Water Absorption |

0.060 % |

0.060 % |

|

Linear Mold Shrinkage |

||

|

Mechanical Properties |

Metric |

English |

|

Tensile Strength |

39.0 MPa |

5660 psi |

|

Elongation at Break |

24 % |

24 % |

|

Flexural Strength |

66.0 MPa |

9570 psi |

|

Flexural Modulus |

2.32 GPa |

336 ksi |

|

Charpy Impact, Notched |

1.90 J/cm² |

9.04 ft-lb/in² |

|

Electrical Properties |

Metric |

English |

|

Volume Resistivity |

1.00e+16 ohm-cm |

1.00e+16 ohm-cm |

|

Surface Resistance |

1.00e+16 ohm |

1.00e+16 ohm |

|

Dielectric Constant |

2.8 |

2.8 |

|

|

2.8 |

2.8 |

|

Dielectric Strength |

29.0 kV/mm |

737 kV/in |

|

Dissipation Factor |

0.00050 |

0.00050 |

|

|

0.00060 |

0.00060 |

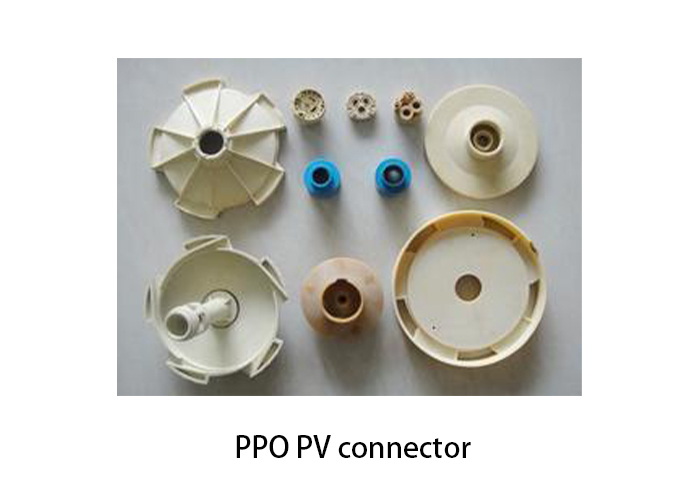

Application range:

Name: Jerry Meng

Mobile:+86 18657312116

Tel:+86 0573-82822319

Whatsapp:+86-18657312116

Email:jerry@fulltrustplastic.com

Add:No. 100 Zhuyuan Road, Jiaxing, China