Polyphenylene oxide (PPO) is one of the world's five general-purpose engineering plastics. It has the advantages of high rigidity, high heat resistance, flame retardant, high strength and excellent electrical properties.

PPO is white granules with good overall performance, can be used in steam at 120 degrees, has good electrical insulation and low water absorption.

It has high heat resistance, the glass transition temperature is 211 degrees, the melting point is 268 degrees, and it has a tendency to decompose when heated to 330 degrees. The higher the content of PPO, the better the heat resistance, and the heat distortion temperature can reach 190 degrees.

PPO polyphenylene ether has high rigidity, low specific gravity, high temperature resistance, creep resistance, good chemical resistance, excellent electrical properties, and is widely used.

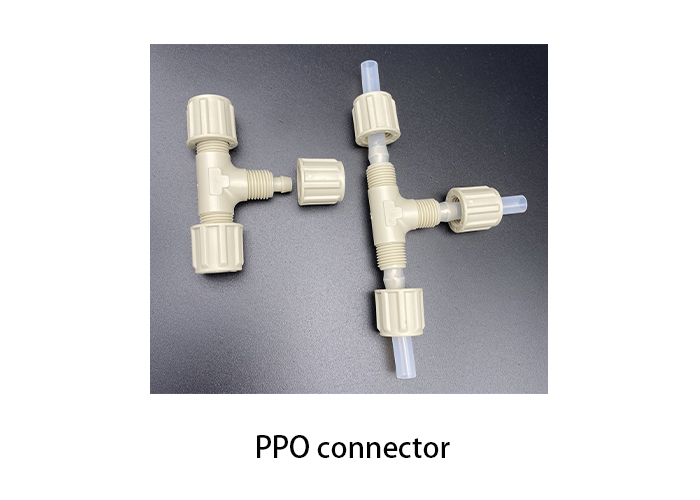

PPO material practical application case:

1. LED reflective cover: excellent shading performance, good heat resistance, good fluidity, good color stability, and good toughness.

2. Charger shell, compressor cover, washing machine electrical box: good acid and alkali resistance, halogen-free flame retardant, good fluidity, rigidity and toughness balance, ultrasonic welding.

3. Puncture clamp: glass fiber reinforced, halogen-free flame retardant, good dimensional stability, arc resistance.

4. Water valve accessories: anti-hydrolysis, high flow, good color stability and good dimensional stability.

5. Water pump and impeller: glass fiber mineral reinforcement, low warpage, hydrolysis resistance, good fluidity.

6. Automotive central electrical junction box: high heat resistance, good high temperature stability, good low temperature toughness, good fluidity, and good dimensional stability.

|

Physical Properties |

Metric |

English |

|

Specific Gravity |

1.07 g/cc |

1.07 g/cc |

|

Moisture Absorption |

0.0600 % |

0.0600 % |

|

Linear Mold Shrinkage |

||

|

Mechanical Properties |

Metric |

English |

|

Tensile Strength, Yield |

59.0 MPa |

8560 psi |

|

Elongation at Break |

50 % |

50 % |

|

Flexural Strength |

83.0 MPa |

12000 psi |

|

Flexural Modulus |

2.06 GPa |

299 ksi |

|

Izod Impact, Notched |

1.96 J/cm |

3.67 ft-lb/in |

|

|

2.45 J/cm |

4.59 ft-lb/in |

|

Electrical Properties |

Metric |

English |

|

Volume Resistivity |

1.00e+16 ohm-cm |

1.00e+16 ohm-cm |

|

Surface Resistance |

1.00e+16 ohm |

1.00e+16 ohm |

|

Dielectric Constant |

2.8 |

2.8 |

|

|

2.8 |

2.8 |

|

Dielectric Strength |

30.0 kV/mm |

762 kV/in |

|

Dissipation Factor |

0.00050 |

0.00050 |

|

|

0.00060 |

0.00060 |

|

Arc Resistance |

80 sec |

80 sec |

Application range:

Name: Jerry Meng

Mobile:+86 18657312116

Tel:+86 0573-82822319

Whatsapp:+86-18657312116

Email:jerry@fulltrustplastic.com

Add:No. 100 Zhuyuan Road, Jiaxing, China