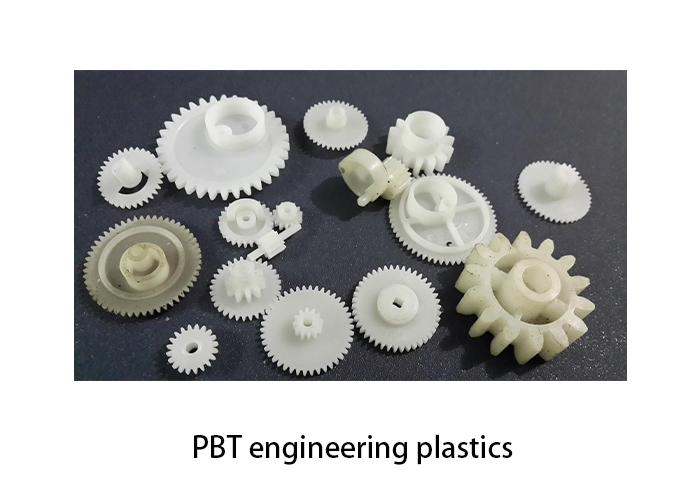

PBT, as an engineering plastic with excellent comprehensive performance, is a new type of engineering plastic with excellent mechanical and electrical properties, chemical corrosion resistance, easy forming, and low moisture absorption. It has been widely used in the fields of electronics, electronics, automobiles, and mechanical manufacturing Automotive sector

The specific applications of PBT engineering plastics in automobiles include ashtray, oil supply system parts, brake system components, accelerator and clutch pedals, intake air grille, air filter housings, motorcycle outer panels, etc.

For example, the spark plug terminal board uses 30% fiberglass reinforced PBT due to its high thermal deformation temperature; The headlight frame is reinforced with 30% fiberglass PBT due to its high thermal deformation temperature, good adhesion to glass metal, and high bending strength.

For example, the main outer side panel of a motorcycle is made of PBT modified with elastomer due to its good appearance, chemical resistance, and low temperature toughness. The door handle is made of thermoplastic double injection glass fiber reinforced PBT, which has the characteristics of weather resistance, chemical resistance, and high stiffness; The ignition system uses fiberglass reinforced PBT, as it requires stress cracking resistance (equipped with metal inserts), dimensional stability, and good electrical insulation.

|

|

|||

|

Physical Properties |

Metric |

English |

Comments |

|

Density |

ASTM D792 |

||

|

Water Absorption |

0.060 % |

0.060 % |

24 hour immersion; ASTM D570 |

|

Linear Mold Shrinkage |

ASTM D955 |

||

|

|

|||

|

Mechanical Properties |

Metric |

English |

Comments |

|

Hardness, Rockwell M |

85 - 90 |

85 - 90 |

ASTM D785 |

|

Tensile Strength, Ultimate |

ASTM D638 |

||

|

Elongation at Break |

50 - 90 % |

50 - 90 % |

ASTM D638 |

|

Flexural Yield Strength |

ASTM D790 |

||

|

Flexural Modulus |

2.20 GPa |

319 ksi |

ASTM D790 |

|

Izod Impact, Notched |

ASTM D256 |

||

|

|

|||

|

Electrical Properties |

Metric |

English |

Comments |

|

Electrical Resistivity |

>= 1.00e+16 ohm-cm |

>= 1.00e+16 ohm-cm |

ASTM D257 |

|

Surface Resistance |

>= 1.00e+14 ohm |

>= 1.00e+14 ohm |

ASTM D257 |

|

Dielectric Constant |

3.3 |

3.3 |

ASTM D150 |

|

Dielectric Strength |

20.0 kV/mm |

508 kV/in |

ASTM D149 |

|

Dissipation Factor |

0.0010 |

0.0010 |

ASTM D150 |

|

Arc Resistance |

120 sec |

120 sec |

ASTM D495 |

|

|

|||

|

Thermal Properties |

Metric |

English |

Comments |

|

CTE, linear |

90.0 µm/m-°C |

50.0 µin/in-°F |

ASTM D696 |

|

Melting Point |

225 °C |

437 °F |

DSC |

|

Deflection Temperature at 0.46 MPa (66 psi) |

155 °C |

311 °F |

ASTM D648 |

|

Deflection Temperature at 1.8 MPa (264 psi) |

60.0 °C |

140 °F |

ASTM D648 |

|

Flammability, UL94 |

HB |

HB |

|

Name: Jerry Meng

Mobile:+86 18657312116

Tel:+86 0573-82822319

Whatsapp:+86-18657312116

Email:jerry@fulltrustplastic.com

Add:No. 100 Zhuyuan Road, Jiaxing, China